PRODUCTS

ABOUT US

Krishana Decoratives, our state of art manufacturing unit is equipped with India's best machineries and equipments and it is designed with the flexibility to produce short run speciality, as well as long run/high volume products for repeat business. We proudly offer the widest range of Plywood for all kind of applications. We constantly renew our machines and develop new techniques to give you the best. The company is better prepared to deliver the best possible solution for your requirement.

The company is known for its technical advancement and modern application because of its good quality. Being an ISO certified company, every step is taken to maintain superb quality control methods for its production.

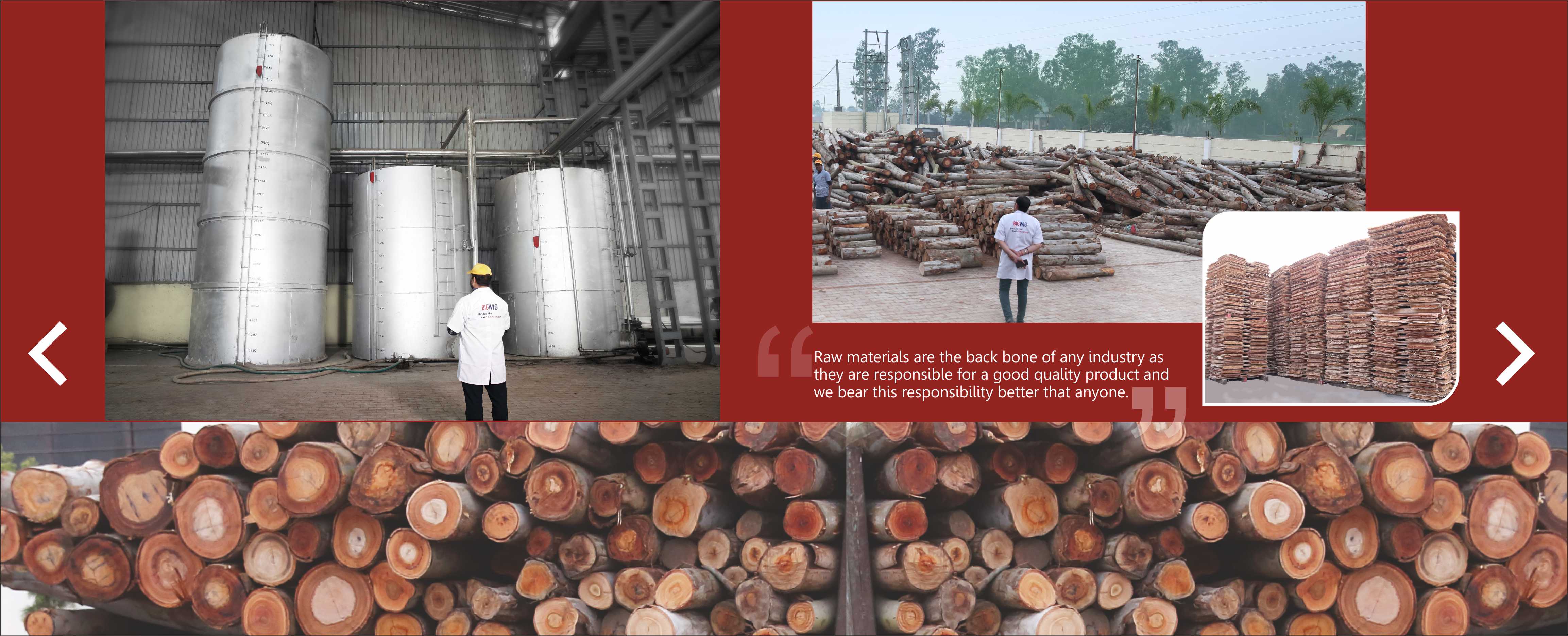

Making of BIGWIG PLYWOOD

Multiple conveyor assembly lines are installed for fast and flawless production of products. Krishna Decorative is one of very few companies that have this assembly line.

Jumbo paper impregnate plant is installed to make smooth and glossy finish of the BIGWIG film face shuttering plywood. It has high production capacity that help to deliver better quality in stipulated time.

Production is supported by numerous assembly tables. For each press there is more than one assembly table. Experience assemblers in the supervision of supervisor do the flawless assembly and special care is taken to avoid the gap or any overlap of core and panel.

Cutting of the plywood is done by double dimension chain saw which insures the precise cutting of the panel. Diamond cutter is used for the smooth side cutting. Utmost care is taken to avoid the deviation of size either ion width or length.